Much of this lecture and the next are

adapted from material in Uman's The Art and Science of

Lightning Protection (Cambridge Univ. Press, 2008;

paperback version 2010). An interesting survey

of the costs of various types of lightning damage can be found

on the first 3 or 4 pages in Chapter 2. Here are are few

examples of the interesting facts and statistics found there:

The 1977 lightning-caused power blackout in

Estimates of the costs of lightning damage

to insurance companies range from 1/3 to $1 billion. In

total about 5% of insurance claims involve lightning (50% in

30,000 house fires are caused every year by lightning. About half of the 20,000 wildfires every year are caused by lightning. The cost of fighting wildfires was about $1.5 billion in 2006 (a record year).

Lightning damage to commercial airlines

costs ~$2 billion per year. Damage to military aircraft is

comparable.

Lightning causes damage to perhaps 100,000 computers/year.

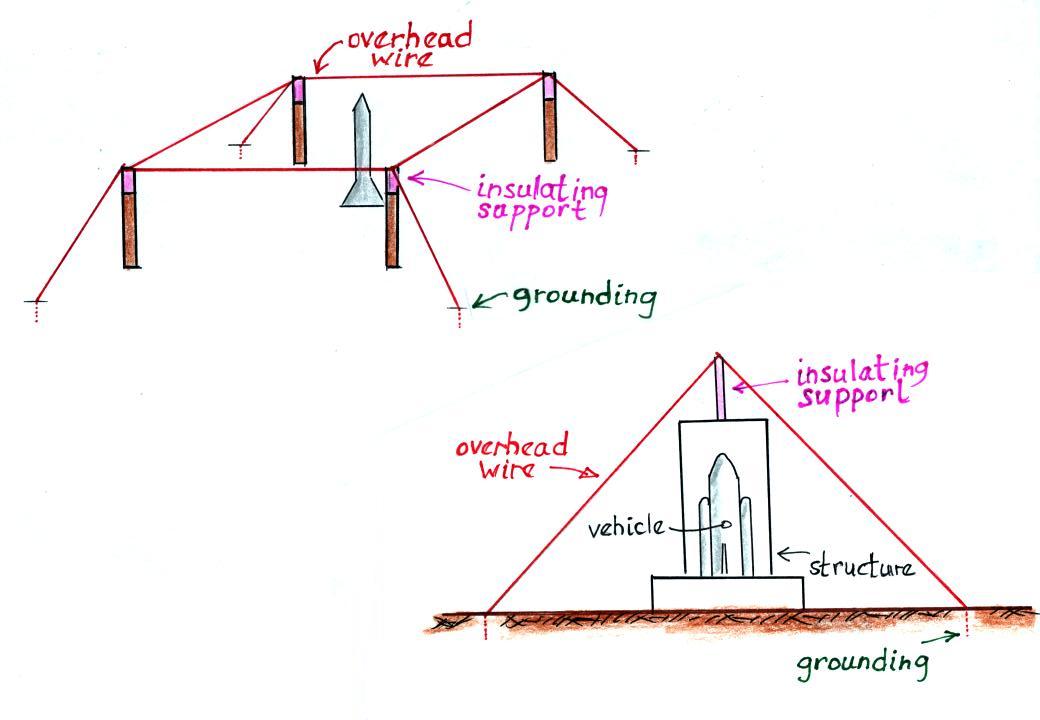

Lightning protection for a house or building usually consists

of 3 components:

For structures less than 50 feet tall

Aa lightning rod provides a

45o or 60o cone

of protection. The 45o

A larger structure can be protected with

multiple rods with overlapping zones of protection.

A different approach is used for larger structures. We

need to recall that the striking distance, d, is the

distance between the leader tip and the ground at the moment

upper connecting discharges are initiated. The leader can

potentially strike anything withing a distance d of the leader

tip.

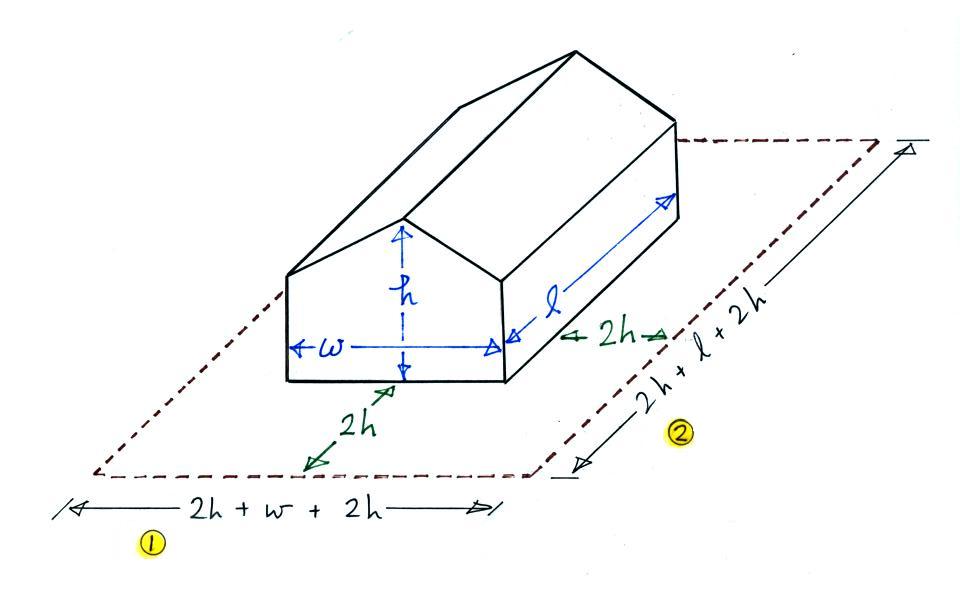

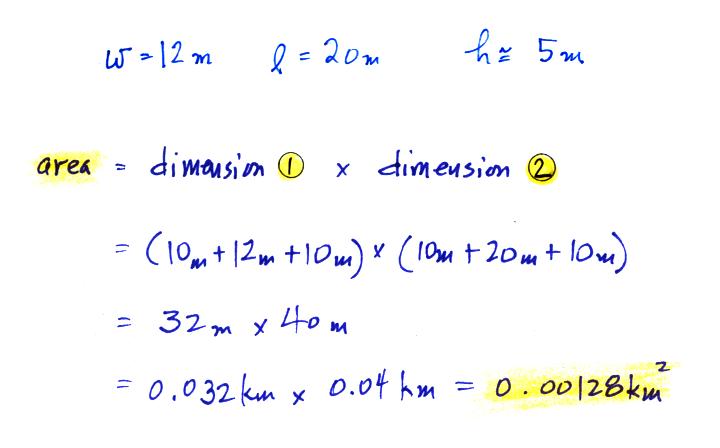

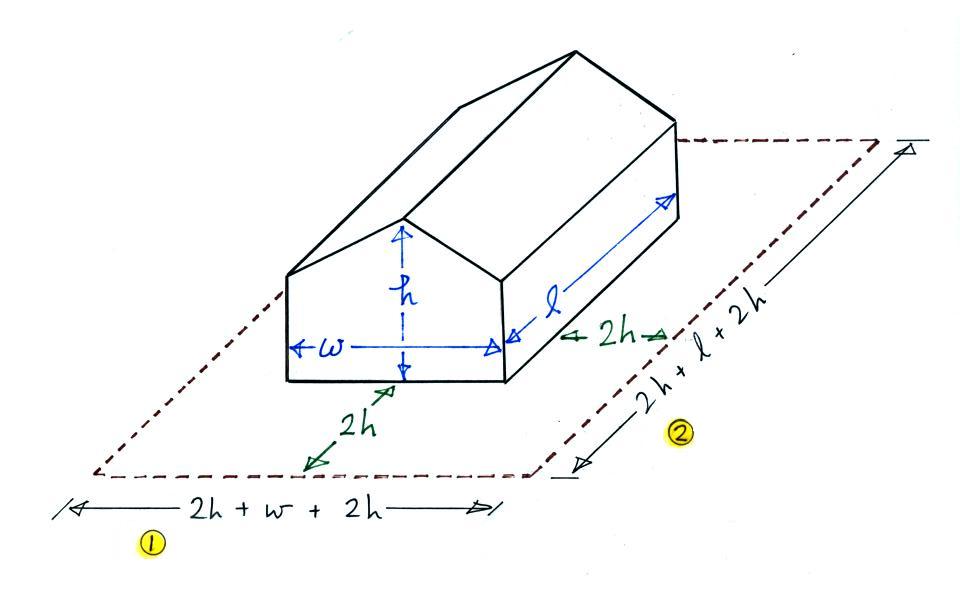

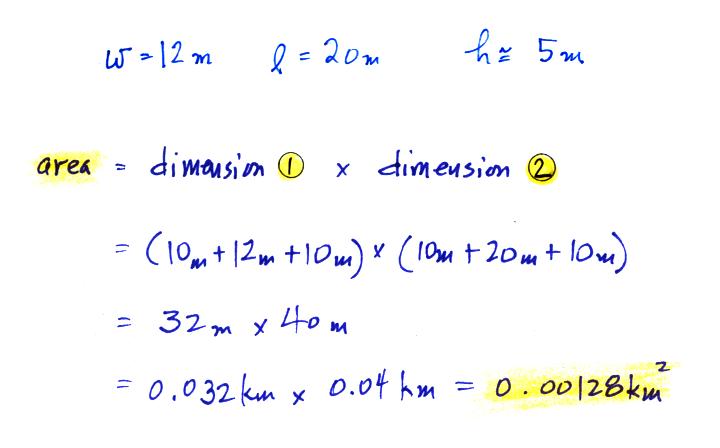

In the rolling sphere method, you imagine rolling a sphere of

radius d (d is the striking distance) over the structure being

evaluated for lightning vulnerability. Parts of the building touched by the sphere are at

risk; those parts of the building could be struck.

Portions that aren't touched are safe.

The height of the building at left is less than or equal to

d. The sides of the building aren't touched by the

sphere, they've been shaded blue and are safe. The

sphere does touch the top of the building, it is

vulnerable. Lightning protection would need to be

installed on the roof. The building at right is quite a

bit higher than d. Much of the sides as well as the roof

can be struck by lightning. Protection would need to be

installed on the top sides of the building and the roof.

Fragments of building materials knocked off the sides of

buildings by lightning are apparently a serious hazard to

people on the street below.

Air terminals could be mounted on the top of a tall

buildings. Additionally, the building designers could

make metal window shades and window frames part of the

lightning protection system by connecting them to the down

conductor.

Note the spacing of the air

terminals must be such that the rolling sphere doesn't touch

the roof in between adjacent lightning rods.

What value of d should be used? Researchers have tried

to relate the striking distance to the amplitude of the peak

return stroke that follows. Generally an expression of

the form

is used. An example

curve is shown below

| protection level |

d |

minimum peak I |

% rs>Imin |

| I |

20 m |

3 kA |

99% |

| II |

30 |

5 |

97 |

| III |

45 |

10 |

91 |

| IV |

60 |

16 |

84 |

Protection of a roof

A roof can be protected by multiple lightning rods.

An old question is whether pointed rods or blunt rods work

best. Some recent research (a couple of recent

studies: "Measurements

of

Lightning

Rod

Responses

to

Nearby

Strikes,"

C.B.

Moore,

G.D.

Aulich,

and

W.

Rison,

Geophys.

Res.

Lett.,

27, 1487-1490, 2000 and "Lightning

Rod Improvement Studies," C.B. Moore, W. Rison, J. Mathis,

G. Aulich, J. Appl. Meteorol., 39, 593-609, 2000

) suggest that the blunt rods might be more effective. The

NFPA allows either type to be used. Rods should be at

least 10 inches tall.

So called "unconventional" rods that use radioactivity or high

voltage to try to initiate an "earlier" upward connecting

discharge are generally not thought to be any more effective

than conventional "Franklin" rods.

A wire mesh

covering the roof of a building or vulnerable installation on

the ground can be used instead of lightning rods. A wire

mesh covered the administration trailer at the rocket triggered

lightning site in Florida for example.

The following table gives recommendations for the spacing of the

wires in a wire mesh (based on Table 4.2 in Uman's "The Art and

Science of Lightning Protection")

| protection level |

d |

mesh spacing |

| I |

20 m |

5 m x 5 m |

| II |

30 |

10 x 10 |

| III |

45 |

15 x 15 |

| IV |

60 |

20 x 20 |

Air terminals should be connected to as

many down conductors as possible. Lightning rods on a

house should be connected to at least two down conductors (at

opposite corners of the house for example).

There are several reasons for this:

(i) The down conductor will have

some resistance and impedance. Connecting inductors or

resistors in parallel reduces the combined impedance.

(ii) The B fields from two down conductors positioned

on opposite sides of a building will point in opposite

directions in the interior of the building.

This will reduce the strength of the B fields inside the

structure and reduce the intensity of voltages and currents

induced in electronic circuits inside the building.

The recommended minimum crossectional area for down conductors is about 50 mm2 for copper (that correcponds to a radius of 4 mm, a diameter of 8 mm or roughly 1/3 inch)

500 kV/m is the average field needed for propagation of

negative polarity leaders

300 kV/m is the average field needed for positive leader

propagation.

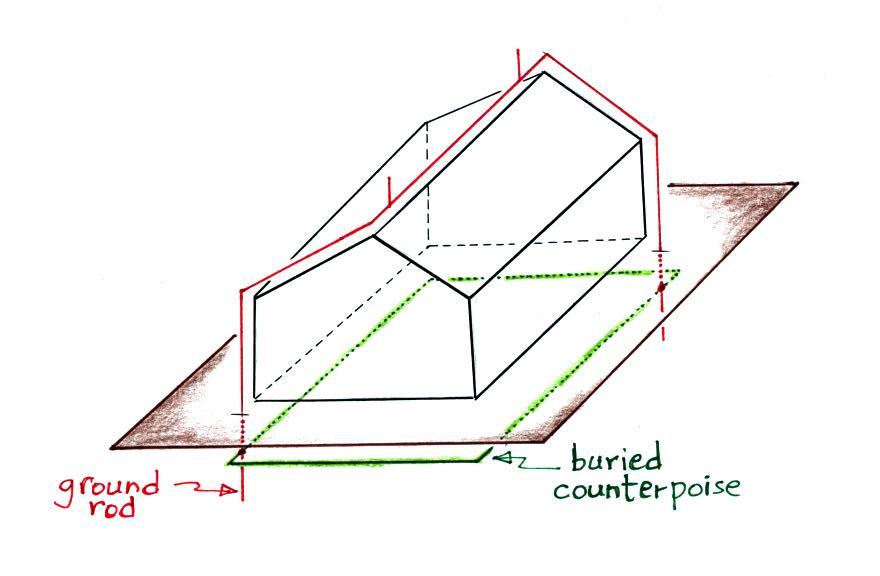

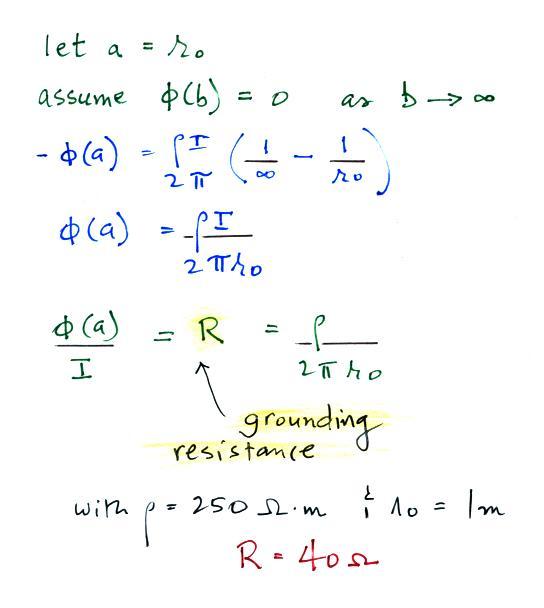

Grounding rods are generally copper clad steel and should

be at least 8 feet long. The bottom end should be at

least 10 feet deep.

Grounding can be improved by connecting grounding rods to a

counterpoise, a loop of grounding wire that encircles the

structure. This reduces potential differences inside the

loop.

Here is a table of resistivities of various materials

(Table 5.1 in Uman's "The Art and Science of Lightning

Protection").

Material

Resistiviy in

ohm-meters

ocean water

0.1 - 0.5

ground, well &

spring water

10 - 150

lake & river

water

100 - 400

rain water

800 - 1300

commercial distilled

water

1000 - 4000

chemically clean

water

250000

clay

25 - 70

sandy clay

40 - 300

peat, marsh &

cultivated soil

50 - 250

sand

1000 -3000

moraine

1000 - 10000

ose (calcereous

remains)

3000 - 30000

| rod length |

resisitivity 100 ohm-meter |

resistivity 1000 ohm-meter |

| 3 m |

35 ohms |

350 ohms |

| 6 |

22 |

220 |

| 9 |

15 |

150 |

| wire length |

resisitivity 100 ohm-meter |

resistivity 1000 ohm-meter |

| 50 m |

4.0 ohms |

40 ohms |

| 100 |

2.6 |

26 |

| 200 |

1.4 |

14 |